- Home Page

- Company Profile

-

Our Products

- Welding Machine

- Zenith Four Head Welding Machine

- UPVC Double Head Welding Machine

- Double Head UPVC Seamless Welding Machine

- Four Head UPVC Welding Machine

- UPVC Window Making Machine

- Single Head UPVC Welding Machine

- Three Head Welding Machine

- Single Head Welding Machine

- UPVC Single Head Welding Machine

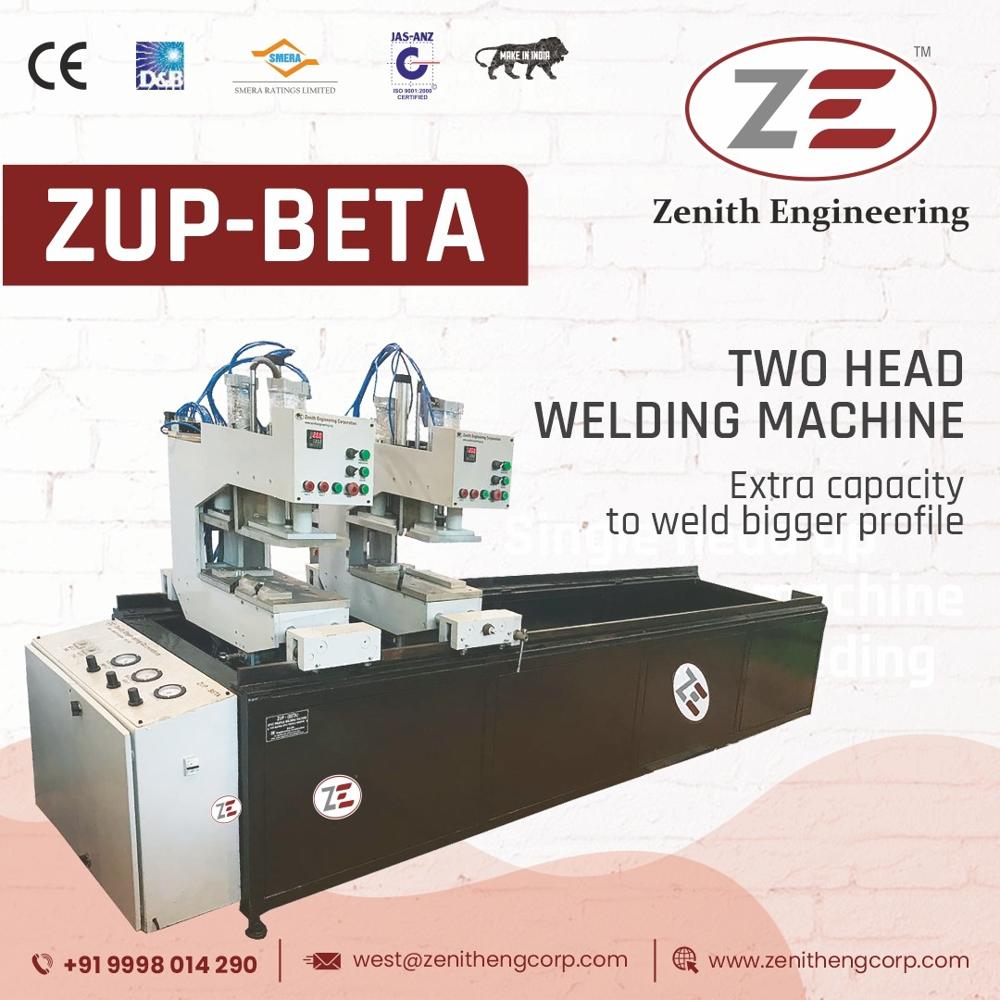

- Two Head UPVC Welding Machine

- Zenith Three Head Welding Machine

- Double Head UPVC Seamless Welding Machine

- Three Head UPVC Seamless Welding Machine

- Punching Machine

- Copy Router Machine

- Corner Cleaning Machine

- Single Head Cutting Machine

- Double Head Cutting Machine

- End Milling Machines

- Cutting Machine

- Heat Sink Aluminum Profile Cutting Machine

- Solar Cutting Machine

- Aluminum Section Cutting Machine

- Double Head UPVC Cutting Machine

- Double Head Frontal Saw

- UPVC Window Cutting Machine

- Single Head Automatic Aluminium Profile Cutting Machine

- Aluminum Cleat Cut Machine

- Aluminum Cutter

- Single Head Upstroking Cutting Machine

- CNC Profile Cutting Machine

- Glazing Bead Saw

- Slot Drill Machine

- Single Head Upstrocking Machines

- V Cutting Saw

- Window Making Machine

- Door Making Machine

- CNC Cleaning Machine

- Curtain Wall Notching Machine

- Aluminium Profile Cutting Services

- Crimping Machine

- Welding Machine

- Gallery

- Contact Us

Window Making Machine

600000 INR/Unit

Product Details:

- Product Type Window Making Machine

- General Use Industrial

- Material Steel Alloy

- Weight (kg) 800 Kilograms (kg)

- Computerized No

- Automatic Yes

- Voltage 220-240 Volt (v)

- Click to view more

X

Window Making Machine Price And Quantity

- 1 Unit

- 600000 INR/Unit

- 600000.00 - 3500000.00 INR/Unit

Window Making Machine Product Specifications

- 800 Kilograms (kg)

- 1 Year

- Window Making Machine

- Yes

- 220-240 Volt (v)

- Steel Alloy

- No

- High Performance, ECO Friendly

- Industrial

- Black & White

- 1250x1350x1500 Millimeter (mm)

Window Making Machine Trade Information

- 10 Unit Per Month

- 10 Days

Product Description

Window Making MachineOffered high performance Window Making Machine requires 380 v voltage and 2.2 kw power to operate. Its punching pressure is 50 kn and punching travel is 30 mm. Approximate dimension of this system is 900 x 900 x 1450 mm. This machine is used for producing aluminum window. Disk based worktable of this equipment contains multiple dies to maintain design precision of produced windows. Each combination punching die of this Window Making Machine has been specially designed so that this machine can adapt to different punching technique. Standard of this machine has been checked on the basis of its dimension, service life, strength, output and user friendliness.

Specifications:

|

Gross Weight |

800 Kg |

|

Production Capacity |

30-50 Window per day |

|

Brand |

Zenith |

|

Air Pressure |

5-7 Bar |

|

Max. Cutter Diameter |

500 mm |

|

Country of Origin |

Made in India |

|

Motor Power |

2.2 kW |

|

Machine Dimension |

1250x1350x1500 mm |

Eco-Conscious, High-Performance Technology

This window making machine combines environmental responsibility with outstanding industrial performance. Its eco-friendly features minimize energy usage and material waste, without sacrificing output or efficiency. Built with a robust steel alloy frame and a modern automatic system, it ensures long-term durability and operational reliability, supporting sustainable manufacturing practices.

Versatile Industrial Application

Designed to fit a wide variety of industrial settings, this machine is suitable for fabricators, manufacturers, suppliers, traders, and other professionals throughout India. Its automatic operation streamlines production processes, allowing users to focus on quality control and customization. With user-friendly controls and a durable build, it's a valuable addition to any facility.

FAQ's of Window Making Machine:

Q: How is this window making machine operated in industrial environments?

A: This window making machine operates automatically, minimizing the need for manual intervention. Its user-friendly interface enables quick setup and smooth integration into industrial manufacturing lines, ensuring efficient window fabrication for large-scale production.Q: What materials are compatible with this window making machine?

A: The machine is constructed from high-quality steel alloy, providing strength and durability for working with various window materials typically used in industrial settings, such as aluminum or UPVC profiles.Q: When should routine maintenance be scheduled for optimal performance?

A: Routine maintenance is advised at regular intervals, ideally every 3-6 months, or as specified in the user manual, to ensure smooth operation and to uphold the 1-year warranty coverage.Q: Where can customers find support and service for this machine in India?

A: Support and service are available nationwide through our established network of dealers, exporters, and service providers. Assistance is provided both during installation and for ongoing maintenance for clients across India.Q: What is the process for installing this machine at an industrial site?

A: Installation involves positioning the machine in a stable area with adequate power supply (220-240V), connecting all safety components, and performing a trial run. Our team assists with setup and provides operational training if required.Q: How does the eco-friendly feature benefit industrial users?

A: Eco-friendly operation reduces energy consumption and minimizes waste, which helps industries lower operational costs and meet environmental compliance more easily while safeguarding productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese