- Home Page

- Company Profile

-

Our Products

- Welding Machine

- Zenith Four Head Welding Machine

- UPVC Double Head Welding Machine

- Double Head UPVC Seamless Welding Machine

- Four Head UPVC Welding Machine

- UPVC Window Making Machine

- Single Head UPVC Welding Machine

- Three Head Welding Machine

- Single Head Welding Machine

- UPVC Single Head Welding Machine

- Two Head UPVC Welding Machine

- Zenith Three Head Welding Machine

- Double Head UPVC Seamless Welding Machine

- Three Head UPVC Seamless Welding Machine

- Punching Machine

- Copy Router Machine

- Corner Cleaning Machine

- Single Head Cutting Machine

- Double Head Cutting Machine

- End Milling Machines

- Cutting Machine

- Heat Sink Aluminum Profile Cutting Machine

- Solar Cutting Machine

- Aluminum Section Cutting Machine

- Double Head UPVC Cutting Machine

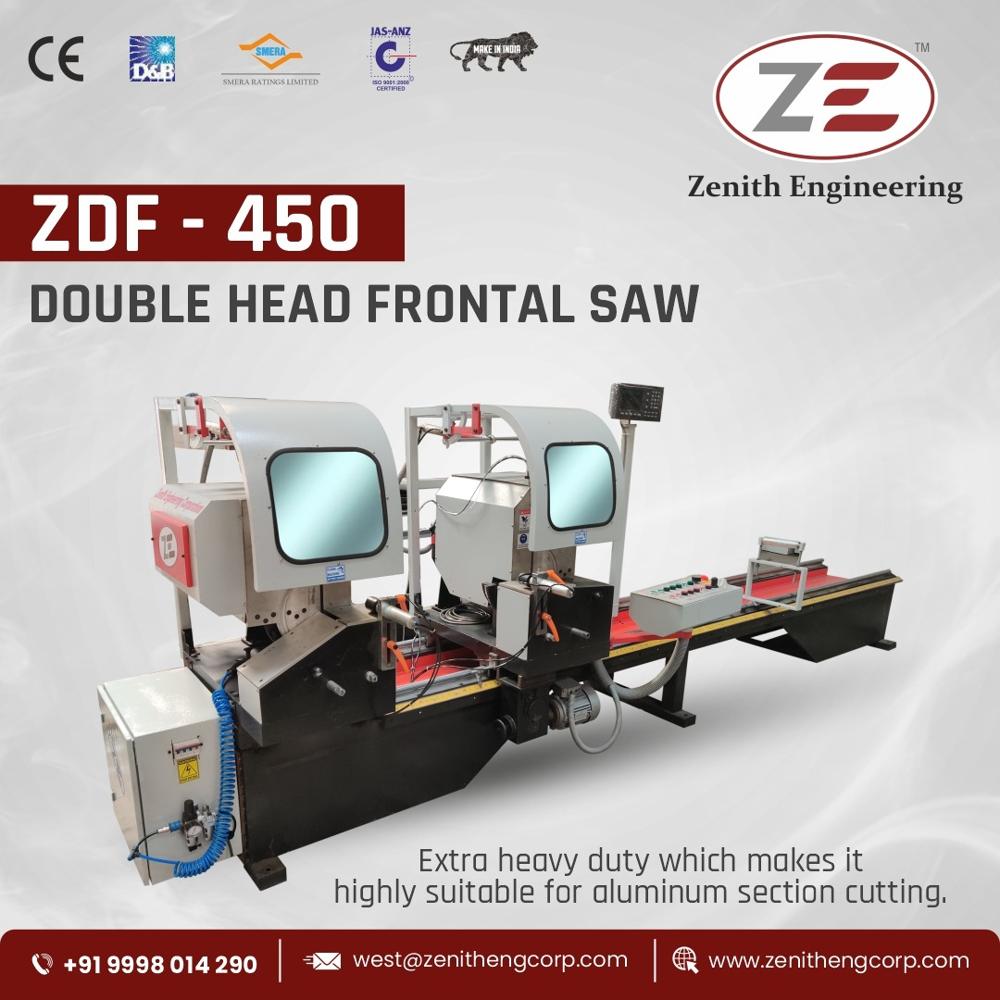

- Double Head Frontal Saw

- UPVC Window Cutting Machine

- Single Head Automatic Aluminium Profile Cutting Machine

- Aluminum Cleat Cut Machine

- Aluminum Cutter

- Single Head Upstroking Cutting Machine

- CNC Profile Cutting Machine

- Glazing Bead Saw

- Slot Drill Machine

- Single Head Upstrocking Machines

- V Cutting Saw

- Window Making Machine

- Door Making Machine

- CNC Cleaning Machine

- Curtain Wall Notching Machine

- Aluminium Profile Cutting Services

- Crimping Machine

- Welding Machine

- Gallery

- Contact Us

Single Head Upstroking Cutting Machine

350000 INR/Unit

Product Details:

- Product Type Single Head Upstroking Cutting Machine

- General Use Industrial

- Material Aluminum

- Type Automatic Cutting Machine

- Computerized No

- Automatic Yes

- Drive Type Electric

- Click to view more

X

Single Head Upstroking Cutting Machine Price And Quantity

- 250000.00 - 400000.00 INR/Unit

- 350000 INR/Unit

- 1 Unit

Single Head Upstroking Cutting Machine Product Specifications

- Aluminum

- Black & White

- Yes

- Automatic Cutting Machine

- 1 Year

- Single Head Upstroking Cutting Machine

- No

- Environmental Friendly, Good Quality

- Industrial

- Electric

Single Head Upstroking Cutting Machine Trade Information

- 10 Unit Per Month

- 10 Days

Product Description

We are a prominent name of the market engaged in manufacturing, supplying and exporting a premium array of Single Head Upstroking Cutting Machine to the customers. It is fitted with an automatic feeding system, which make sure their time & energy saving operation. Different types of vegetables can be slashes and cut in no time with the help of our offered machine. Also, with the help of our qualified logistics team, we make sure to provide this Single Head Upstroking Cutting Machine timely.

|

Air Pressure |

5-7 Bar |

|

Voltage |

340 V |

|

Model Name/Number |

ZUP-22 |

|

Power |

3 HP |

|

Phase |

Three Phase |

|

Saw Blade Size |

600 mm |

|

Motor Power |

2.2 to 3.5 kW |

|

Max Cutter Dia |

420 mm |

|

Machine Dimension |

700(L)x700(W)x1400(H) mm |

|

Gross Weight |

375 Kg |

Efficient Automatic Cutting

This machine leverages advanced upstroke technology to provide accurate and consistent cuts automatically. Its electric drive and sturdy aluminum construction guarantee longevity and minimal maintenance, making it ideal for industrial applications where productivity is paramount.

Environmentally Conscious Design

With a focus on reducing waste and energy consumption, this cutting machine adheres to environmentally friendly standards. Its efficient operation not only supports sustainability initiatives but also maximizes the use of raw materials for better yield.

FAQ's of Single Head Upstroking Cutting Machine:

Q: How does the Single Head Upstroking Cutting Machine operate without computerized controls?

A: The machine is engineered for automatic operation via a user-friendly interface, allowing users to set cutting parameters manually without the need for computer integration. Its intuitive design ensures ease of use for operators of all expertise levels.Q: What materials can the machine cut effectively?

A: Constructed from aluminum and equipped with robust blades, the machine is suitable for cutting a wide range of industrial materials, including metals, plastics, and certain composites, depending on blade compatibility.Q: When is periodic maintenance required for optimal performance?

A: Basic maintenance, such as blade inspection and cleaning, should be performed regularly, typically on a weekly basis or according to the manufacturer's guidelines, to ensure optimal performance and prolong the machine's lifespan.Q: Where is this cutting machine commonly utilized?

A: This automatic cutting machine is widely adopted in factories, workshops, and large-scale production facilities throughout India, serving industrial applications like fabrication, manufacturing, and material processing.Q: What is the process for adjusting the cutting settings?

A: Operators can easily adjust cutting depth and speed through the machine's manual control panel. No advanced programming is required, streamlining setup for different materials and applications.Q: Why is this machine considered environmentally friendly?

A: The machine is designed to minimize energy usage and material waste, which supports eco-friendly production practices. Its precision cuts reduce off-cuts and resource consumption, benefiting both the environment and operational costs.Q: What are the key benefits of using this automatic cutting machine in industrial operations?

A: The primary advantages include increased production efficiency, consistent cutting quality, reduced human labor, and a safer working environment, all backed by a full 1-year warranty and suitable for a wide network of commercial and industrial users.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese