- Home Page

- Company Profile

-

Our Products

- Welding Machine

- Zenith Four Head Welding Machine

- UPVC Double Head Welding Machine

- Double Head UPVC Seamless Welding Machine

- Four Head UPVC Welding Machine

- UPVC Window Making Machine

- Single Head UPVC Welding Machine

- Three Head Welding Machine

- Single Head Welding Machine

- UPVC Single Head Welding Machine

- Two Head UPVC Welding Machine

- Zenith Three Head Welding Machine

- Double Head UPVC Seamless Welding Machine

- Three Head UPVC Seamless Welding Machine

- Punching Machine

- Copy Router Machine

- Corner Cleaning Machine

- Single Head Cutting Machine

- Double Head Cutting Machine

- End Milling Machines

- Cutting Machine

- Heat Sink Aluminum Profile Cutting Machine

- Solar Cutting Machine

- Aluminum Section Cutting Machine

- Double Head UPVC Cutting Machine

- Double Head Frontal Saw

- UPVC Window Cutting Machine

- Single Head Automatic Aluminium Profile Cutting Machine

- Aluminum Cleat Cut Machine

- Aluminum Cutter

- Single Head Upstroking Cutting Machine

- CNC Profile Cutting Machine

- Glazing Bead Saw

- Slot Drill Machine

- Single Head Upstrocking Machines

- V Cutting Saw

- Window Making Machine

- Door Making Machine

- CNC Cleaning Machine

- Curtain Wall Notching Machine

- Aluminium Profile Cutting Services

- Crimping Machine

- Welding Machine

- Gallery

- Contact Us

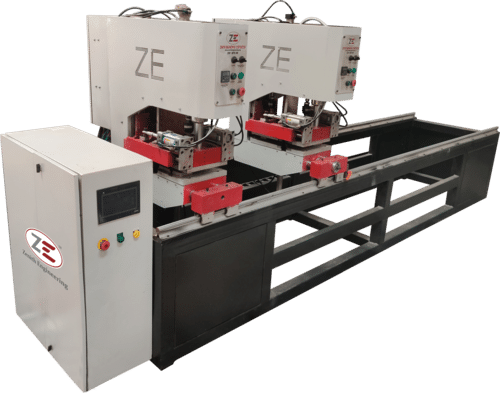

Double Head UPVC Seamless Welding Machine

650000.0 INR/Piece

Product Details:

- Cooling Method Air cooling

- Voltage 220 Volt (v)

- Usage Industrial

- Function to weld colour UPVC profiles.

- Dimension (L*W*H) 4300x1150x1850 Millimeter (mm)

- Weight 1200 Kilograms (kg)

- Condition New

- Click to view more

X

Double Head UPVC Seamless Welding Machine Price And Quantity

- 300000.00 - 600000.00 INR/Piece

- 650000.0 INR/Piece

- 1 Piece

Double Head UPVC Seamless Welding Machine Product Specifications

- 1200 Kilograms (kg)

- 220 Volt (v)

- Air cooling

- to weld colour UPVC profiles.

- Industrial

- 4300x1150x1850 Millimeter (mm)

- 50 Hertz (HZ)

- Double Head UPVC Seamless Welding Machine

- Mild Steel

- New

Double Head UPVC Seamless Welding Machine Trade Information

- Cheque

- 50 Piece Per Month

- 15 Days

- Wooden Pallets

- All India

- ISO 9001:2000

Product Description

Double Head UPVC Seamless Welding Machine

Our enterprise has gained immense recognition in manufacturing and supplying quality assured array of Double Head UPVC Seamless Welding Machine. This machine is manufactured with the help of leading-edge technology and is widely demanded in engineering industry for joining two or more metal surfaces or parts. Provided machine is made in complete compliance with predefined market norms at our well-equipped manufacturing unit. Moreover, this Double Head UPVC Seamless Welding Machine is extensively appreciated in the market due to its strong design and excellent performance.

Features:

- Excellent performance

- High corrosion resistance

- Withstands high temperature

- Easy to operate

Specifications:

|

Air consumption |

200 l/min ( 6-7 Bar needed for continue operation) |

|

Weight |

1200 kg |

|

Model Name/Number |

ZUP-BETA-SM |

|

Automation Grade |

Semi-Automatic |

|

Brand |

Zenith |

|

Country of Origin |

Made in India |

|

Working Pressure |

0.4-0.6 Mpa |

|

Welding Length |

400-3900mm |

|

Welding Height |

20-140mm |

|

Dimension |

4300x1150x1850 mm |

Engineered for Industrial Excellence

Designed for demanding industrial environments, our Double Head UPVC Seamless Welding Machine delivers unmatched performance in welding UPVC profiles. Its heavy-duty construction ensures long-term durability, supporting high-output manufacturing with precision. Whether you're a wholesaler or a fabricator, this machine provides seamless, reliable joints, boosting your productivity and product quality.

Advanced Features for Seamless Results

The double-head design enables simultaneous welding of two profiles, significantly reducing processing times. Its seamless technology eliminates visible weld lines, producing smooth and aesthetically pleasing joints. With user-friendly controls and robust safety features, the machine offers efficient operation and consistently high-quality results every time.

FAQ's of Double Head UPVC Seamless Welding Machine:

Q: How does the Double Head UPVC Seamless Welding Machine function?

A: This machine uses heated plates and precise pressure to weld UPVC profiles together at two simultaneous points, ensuring seamless and strong joints without visible lines. The operator can control the temperature and pressure for optimal welding quality.Q: What are the main benefits of using a double head configuration?

A: A double head design allows two welds to be performed at the same time, which doubles productivity while ensuring uniform alignment and seam quality. This results in faster project completion and higher manufacturing efficiency.Q: When is it recommended to use this machine in production processes?

A: This machine is best suited for high-volume manufacturing of UPVC doors and windows, especially when seamless joints are required for aesthetic or structural reasons. It is ideal during the assembly phase after profile cutting.Q: Where can the Double Head UPVC Seamless Welding Machine be utilized in India?

A: It can be used in industrial workshops, factory production lines, and fabrication units across India, wherever large-scale UPVC profile welding is necessary. Dealers, exporters, manufacturers, and suppliers commonly employ it.Q: What is the standard process for operating the machine safely and efficiently?

A: Operators should securely position the UPVC profiles, select the correct temperature and pressure settings, and ensure all safety measures are followed. Regular maintenance and inspection of welding heads are advised for consistent performance.Q: How does seamless welding improve UPVC product quality?

A: Seamless welding removes visible joint lines, resulting in a smoother, more attractive finish. It also enhances the mechanical strength of the welded profiles, providing durable and long-lasting UPVC products.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese