- Home Page

- Company Profile

-

Our Products

- Welding Machine

- Zenith Four Head Welding Machine

- UPVC Double Head Welding Machine

- Double Head UPVC Seamless Welding Machine

- Four Head UPVC Welding Machine

- UPVC Window Making Machine

- Single Head UPVC Welding Machine

- Three Head Welding Machine

- Single Head Welding Machine

- UPVC Single Head Welding Machine

- Two Head UPVC Welding Machine

- Zenith Three Head Welding Machine

- Double Head UPVC Seamless Welding Machine

- Three Head UPVC Seamless Welding Machine

- Punching Machine

- Copy Router Machine

- Corner Cleaning Machine

- Single Head Cutting Machine

- Double Head Cutting Machine

- End Milling Machines

- Cutting Machine

- Heat Sink Aluminum Profile Cutting Machine

- Solar Cutting Machine

- Aluminum Section Cutting Machine

- Double Head UPVC Cutting Machine

- Double Head Frontal Saw

- UPVC Window Cutting Machine

- Single Head Automatic Aluminium Profile Cutting Machine

- Aluminum Cleat Cut Machine

- Aluminum Cutter

- Single Head Upstroking Cutting Machine

- CNC Profile Cutting Machine

- Glazing Bead Saw

- Slot Drill Machine

- Single Head Upstrocking Machines

- V Cutting Saw

- Window Making Machine

- Door Making Machine

- CNC Cleaning Machine

- Curtain Wall Notching Machine

- Aluminium Profile Cutting Services

- Crimping Machine

- Welding Machine

- Gallery

- Contact Us

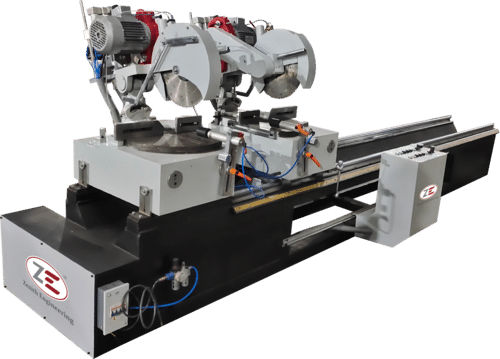

Double Head Alumminium Cutter Machine

575000.0 INR/Piece

Product Details:

- Product Type Double Head Alumminium Cutter Machine

- General Use Industrial

- Material Aluminum

- Type Automatic Cutting Machine

- Weight (kg) 1125 Kilograms (kg)

- Computerized No

- Automatic Yes

- Click to view more

X

Double Head Alumminium Cutter Machine Price And Quantity

- 575000.0 INR/Piece

- 1 Piece

- 350000.00 - 550000.00 INR/Piece

Double Head Alumminium Cutter Machine Product Specifications

- Environmental Friendly, Good Quality

- Gray

- Electric

- Industrial

- 1125 Kilograms (kg)

- No

- 380 Volt (v)

- Aluminum

- 2800 RPM

- 5650x1100x1450 Millimeter (mm)

- 1 Year

- Yes

- Automatic Cutting Machine

- Double Head Alumminium Cutter Machine

Double Head Alumminium Cutter Machine Trade Information

- VADODARA

- Cheque, Cash Advance (CA), Cash in Advance (CID)

- 50 Piece Per Month

- 15 Days

- Wooden Pallets

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India, Lakshadweep, Dadra and Nagar Haveli, Assam, Arunachal Pradesh, Sikkim, Bihar, Jharkhand, Karnataka, Telangana, Andhra Pradesh, Jammu and Kashmir, Uttar Pradesh, Madhya Pradesh, Delhi, North India, Tripura, Mizoram, Punjab, Rajasthan, Chhattisgarh, Maharashtra, Tamil Nadu, Himachal Pradesh, Kerala, Haryana, Nagaland, Odisha, South India, Meghalaya, Pondicherry, Daman and Diu, West India, Uttarakhand, Central India, Chandigarh, Gujarat, Goa, Andaman and Nicobar Islands, Manipur, East India

- ISO 9001:2015

Product Description

Double Head Alumminium Cutter Machine

If you are planning to buy a cutting machine for your unit which comes with a high cutting capacity and can precisely cut aluminium or PVC profile, then buy a double head cutting saw. This machine features 450mm and 550mm diameter saw blades. This machine can be used for cutting PVC profiles, aluminium profiles, doors and windows using circular blades. This machine features electro-pneumatic inclination and numerical control of moving head. Cut with high cutting precision, this double head cutting saw can be used for batch production.

Product Details:

|

Minimum Order Quantity |

1 Piece |

|

Brand |

ZENITH |

|

Usage |

Industrial |

Specifications:

|

Gross Weight |

1125 Kg |

|

Brand/Make |

Zenith |

|

Air Consumption |

5-7 Bar |

|

Motor Rotary Speed |

2800 RPM |

|

Country of Origin |

Made in India |

|

Phase |

3 Phase |

|

Motor Power |

1.5-2 kW |

|

Model Number |

ZDVH-14 |

|

Max. Cutter Dia |

350 mm |

|

Machine Dimension |

5650x1100x1450 mm |

|

Saw Blade |

450, 550 mm |

Superior Automatic Cutting Precision

This double head cutter machine delivers high-accuracy aluminum cutting with automatic functionality, making it highly efficient for industrial use. Its heavy-duty structure and electric drive enable consistent performance, especially in demanding fabrication environments. Designed to be user-friendly, it reduces manual labor and enhances productivity.

Robust and Reliable Construction

Made from high-grade aluminum and weighing 1125 kg, the machine stands out for its durability and stability. The environmental-friendly design ensures minimal waste, while top-notch quality components increase its lifespan. A warranty of one year adds to customer confidence in its reliability.

Versatile Distribution Network Across India

Whether you are a dealer, exporter, manufacturer, or end-user, this machine is available through a widespread supply chain across India. Retailers, traders, and wholesalers ensure smooth accessibility, while fabricators and producers benefit from tailored support and services.

FAQ's of Double Head Alumminium Cutter Machine:

Q: How does the Double Head Aluminum Cutter Machine operate automatically?

A: This machine uses an electric drive system to automate the cutting process. Once set up, both heads can cut aluminum materials efficiently without continuous manual intervention, increasing workflow speed and accuracy.Q: What are the main benefits of using this cutting machine in industrial settings?

A: Key benefits include precise aluminum cutting, reduced manual labor, improved productivity, and a design that minimizes environmental impact. Its automatic operation and robust build also ensure long-term effectiveness and reliability.Q: When should I consider using a double head cutter over a single head machine?

A: A double head cutter is ideal when your production tasks require simultaneous or consecutive cuts on aluminum pieces, reducing processing times and boosting output compared to a single head machine.Q: Where can I purchase or source this machine in India?

A: This double head aluminum cutter is widely available across India through authorized dealers, exporters, manufacturers, suppliers, retailers, traders, fabricators, and wholesalers. You can source it directly from manufacturers or through reliable industrial equipment suppliers.Q: What is the installation process for this machine?

A: Installation typically involves positioning the machine at your facility, connecting it to the electrical source, and calibrating the cutting heads. Manufacturers or suppliers often provide guidance and support to ensure correct setup.Q: How is the machine environmentally friendly?

A: It is designed to minimize material waste during cutting and employs energy-efficient components. This helps in reducing the overall environmental footprint compared to traditional cutting methods.Q: What warranty and support options are available?

A: The Double Head Aluminum Cutter Machine comes with a standard 1-year warranty covering manufacturing defects. Authorized dealers and manufacturers also offer after-sales support and maintenance services.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese