- Home Page

- Company Profile

-

Our Products

- Welding Machine

- Zenith Four Head Welding Machine

- UPVC Double Head Welding Machine

- Double Head UPVC Seamless Welding Machine

- Four Head UPVC Welding Machine

- UPVC Window Making Machine

- Single Head UPVC Welding Machine

- Three Head Welding Machine

- Single Head Welding Machine

- UPVC Single Head Welding Machine

- Two Head UPVC Welding Machine

- Zenith Three Head Welding Machine

- Double Head UPVC Seamless Welding Machine

- Three Head UPVC Seamless Welding Machine

- Punching Machine

- Copy Router Machine

- Corner Cleaning Machine

- Single Head Cutting Machine

- Double Head Cutting Machine

- End Milling Machines

- Cutting Machine

- Heat Sink Aluminum Profile Cutting Machine

- Solar Cutting Machine

- Aluminum Section Cutting Machine

- Double Head UPVC Cutting Machine

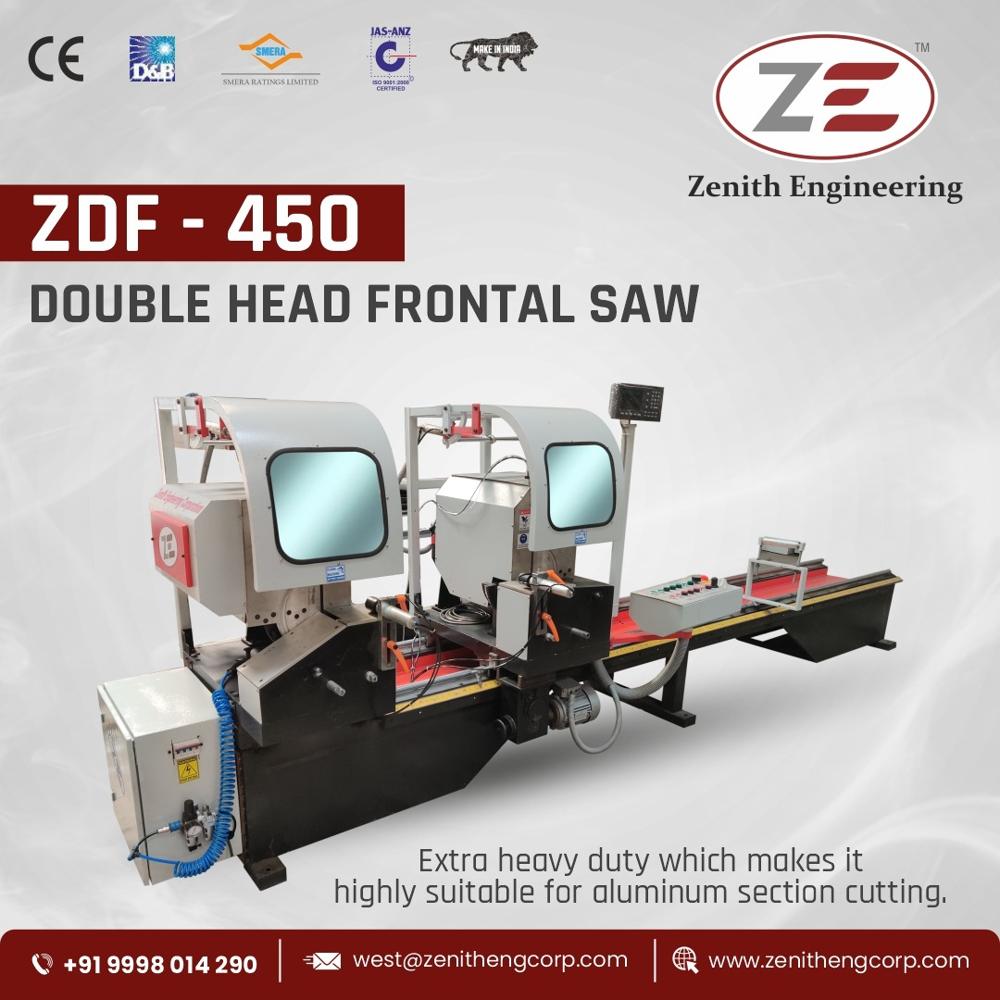

- Double Head Frontal Saw

- UPVC Window Cutting Machine

- Single Head Automatic Aluminium Profile Cutting Machine

- Aluminum Cleat Cut Machine

- Aluminum Cutter

- Single Head Upstroking Cutting Machine

- CNC Profile Cutting Machine

- Glazing Bead Saw

- Slot Drill Machine

- Single Head Upstrocking Machines

- V Cutting Saw

- Window Making Machine

- Door Making Machine

- CNC Cleaning Machine

- Curtain Wall Notching Machine

- Aluminium Profile Cutting Services

- Crimping Machine

- Welding Machine

- Gallery

- Contact Us

Aluminum Section Cutting Machine

650000 INR/Unit

Product Details:

- Product Type Aluminum Section Cutting Machine

- General Use Industrial

- Material Aluminum

- Type Automatic Cutting Machine

- Weight (kg) 1550 Kilograms (kg)

- Computerized No

- Automatic Yes

- Click to view more

X

Aluminum Section Cutting Machine Price And Quantity

- 650000 INR/Unit

- 1 Unit

- 650000.00 - 1800000.00 INR/Unit

Aluminum Section Cutting Machine Product Specifications

- Environmental Friendly, Good Quality

- 380 Volt (v)

- 1 Year

- Automatic Cutting Machine

- Yes

- 1550 Kilograms (kg)

- Aluminum

- No

- Aluminum Section Cutting Machine

- Electric

- Industrial

Aluminum Section Cutting Machine Trade Information

- 10 Unit Per Month

- 10 Days

Product Description

Due to of our advanced research and development department, we are professionally engaged in manufacturing Aluminum Section Cutting Machine. Under the strict vigilance of our engineers these bar cutting machines are made by our experts using supreme quality metals. Find usage for cutting bars of different metals in different sizes, these cutting machines are provided to our clients at unbeatable prices. In addition to this, Aluminum Section Cutting Machine is available in varied specifications.

|

Frequency |

50 Hz |

|

Usage |

Angle Cutting,Rod Cutting,Plate Cutting |

|

Material to be Cut |

Aluminium & UPVC |

|

Capacity |

6000 Piece/day |

|

Weight |

1550 Kg |

|

Voltage |

380 V |

|

Width |

1500 mm |

|

Length |

6000 mm |

|

Height |

2000 mm |

Efficient Industrial Automation

Engineered for seamless automation, this aluminum cutting machine enhances production speed and accuracy in industrial settings. Its electric-driven, fully automatic operation minimizes manual labor, providing consistent results for fabricators, manufacturers, and traders. Designed for continuous use, it fits well into diverse industrial workflows.

Quality and Environmental Benefits

Featuring robust construction and utilizing 380V electric power, the machine ensures reliable and consistent cutting quality. Its environmentally friendly design reduces emissions and waste, supporting sustainable manufacturing practices. Backed by a 1-year warranty, it promises dependable performance and ease of maintenance.

FAQ's of Aluminum Section Cutting Machine:

Q: How does the automatic aluminum section cutting machine operate?

A: The machine operates using an electric drive system, which automates the entire section cutting process without requiring a computerized interface. Operators simply load the aluminum material, and the machine performs precise cuts automatically, enhancing efficiency and reducing manual intervention.Q: What materials and thicknesses can the machine handle?

A: Designed specifically for aluminum sections, this machine is built to handle a variety of industrial-grade aluminum profiles. For specific thickness capacities, users should refer to the manufacturer's guidelines, but it is ideal for standard industrial aluminum cutting tasks.Q: When should I perform maintenance on this cutting machine?

A: Routine maintenance should follow the manufacturer's recommendations, typically involving regular checks after a certain number of operating hours or at least quarterly. This ensures optimal performance and helps maintain the validity of the one-year warranty.Q: Where can I purchase this aluminum cutting machine in India?

A: The machine is available through a wide network of dealers, exporters, manufacturers, suppliers, and wholesalers across India. Interested buyers can also consult local fabricators or regional retailers for purchase and installation services.Q: What is the process for installing the automatic cutting machine?

A: Installation generally involves securing the machine in an industrial workspace with access to a 380V power supply. Professional installation by certified technicians is recommended to ensure all safety and operational standards are met.Q: How is this machine environmentally friendly?

A: This machine utilizes efficient electric power, minimizing energy consumption and reducing emissions compared to conventional cutting methods. It is engineered to limit material waste, supporting eco-friendly industrial operations.Q: What are the key benefits of using this machine for aluminum cutting?

A: Key benefits include high cutting precision, consistent quality, reduced manual labor, and improved operational speed. Its automatic and electric-driven design lowers long-term operational costs and supports environmentally responsible manufacturing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese